25 Feb 2020 A Test You May Not Want to Skip – Floor Flatness and its Importance

Many of us in the Engineering and Construction Fields are familiar with concrete and its many properties; compressive strength, air entrainment, slump, and so on. What some might not be as familiar with is the concept of flatness and levelness as it pertains to concrete slabs. How those measurements are conducted and how different end uses require varying degrees of flatness and levelness are interesting items to consider when planning a project. Oftentimes this type of testing is one of the more misunderstood testing requirements involved in concrete inspections. Many projects disregard it and don’t get the testing done which could result in uneven flooring. By the time the uneven flooring is discovered it is closer to the end of the project and the cost to get it fixed would require unanticipated additional funding.

Floor Flatness is a measurement of how close a section of concrete is to planar, or more simply whether the concrete slab has bumps of waves as you move across the slab. Floor Levelness is how close a section of concrete is to its intended slope (usually 0). Think about two different types of roadways. One being a dirt road in the planes of Nebraska and the other being an asphalt road in the hills of West Virginia. While the first road is not very flat, it does maintain a constant horizontal slope and typically is very level; the second road is a very smooth road, aka flat, but due to the changing terrain of going up and down hills, it is not very level.

Floor Flatness is a measurement of how close a section of concrete is to planar, or more simply whether the concrete slab has bumps of waves as you move across the slab. Floor Levelness is how close a section of concrete is to its intended slope (usually 0). Think about two different types of roadways. One being a dirt road in the planes of Nebraska and the other being an asphalt road in the hills of West Virginia. While the first road is not very flat, it does maintain a constant horizontal slope and typically is very level; the second road is a very smooth road, aka flat, but due to the changing terrain of going up and down hills, it is not very level.

The testing of a concrete slabs flatness and levelness is governed by ASTM E1155 and gives (2) two numerical values, FF for Flatness and FL for Levelness. For each characteristic, both FF and FL, the standard gives us both a local and overall value that must be met by the section of slab poured in any particular day and the overall slab characteristic when all the slabs are finished for any given floor of concrete, respectively. Not every concrete slab pour must meet the overall FF and FL values, but every slab must meet the local value and when combined with other values from each subsequent pours for that floor, they must average out to be above the overall FF and FL values. ASTM E1155 outlines, the number of data points required and in what direction for both FF and FL. Floor Flatness is measured by tracking the difference in elevation between two points 1 foot apart and comparing them with every other 1-foot elevation change across a measured distance or “run.” Floor Levelness on the other hand compares the change in elevation over a distance of 10 feet, by determining the net change in elevation over 10 data points within the run.

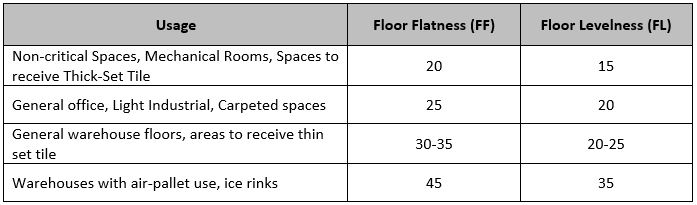

This begs an obvious question for owners or concrete contractors; Do I really need a super flat or level floor, or can I get away with a slab that visually looks fine? The answer to that depends on the purpose you have for your space. The table below outlines typical uses for slabs that require differing levels of Floor Flatness and Levelness.

Basically, when the floor is to remain uncovered and serves to be a foundation for higher structures or has limited tolerances based on the flooring selected, the floor has a higher and more stringent FF and FL requirement.

Floor Flatness testing is a common testing procedure for large floor slabs, but does come with a high entry equipment cost.  With some testing devices and the software to run them, the total amount is approximately $10,000 for a new device. This does not include the cost of certifying personnel through the manufacture to run and correctly execute the ASTM E1155 Standard. KBJW has certified personnel on staff that have run this testing procedure for over 10 years totaling millions of square feet tested. KBJW is happy to assist in this or any other test method that you may have for your upcoming project. We have the experience and capacity to meet most needs.

With some testing devices and the software to run them, the total amount is approximately $10,000 for a new device. This does not include the cost of certifying personnel through the manufacture to run and correctly execute the ASTM E1155 Standard. KBJW has certified personnel on staff that have run this testing procedure for over 10 years totaling millions of square feet tested. KBJW is happy to assist in this or any other test method that you may have for your upcoming project. We have the experience and capacity to meet most needs.

Please to not hesitate to contact Ben Jackson at (804-894-3517) or via email to discuss your upcoming project.